Concept: To make the robot run, it is necessary to install a transmission device for each joint, that is, each degree of freedom of movement. Function: Provide the motive force for the actions of each part of the robot and each joint.

Drive system: It can be hydraulic drive, pneumatic drive, electric drive, or a comprehensive system combining them; it can be direct drive or indirect drive through mechanical transmission mechanisms such as synchronous belts, chains, gear trains, and harmonic gears.

1. Electric drive device

The electric drive device has simple energy, large speed range, high efficiency, and high speed and position accuracy. However, they are mostly connected with deceleration devices, and it is difficult to drive directly.

Electric drive devices can be divided into direct current (DC), alternating current (AC) servo motor drives and stepper motor drives. DC servo motor brushes are easy to wear and sparks are easy to form. Brushless DC motors have also been used more and more widely. Stepper motor drives are mostly open-loop control, with simple control but low power, and are mostly used in low-precision and low-power robot systems.

The following checks must be made before electric power-on operation:

1) Whether the power supply voltage is appropriate (overvoltage is likely to cause damage to the drive module); The +/- polarity of the DC input must not be connected wrongly, and whether the motor model or current setting value on the drive controller is appropriate (not at the beginning Too big);

2) The control signal line is connected firmly, and the shielding problem should be considered in the industrial field (such as using twisted pair);

3) Don't connect all the wires that need to be connected at the beginning, only connect to the most basic system, and then gradually connect after it runs well.

4) Be sure to figure out the grounding method, or use floating without connecting.

5) Closely observe the state of the motor within half an hour of starting operation, such as whether the movement is normal, the sound and the temperature rise, and immediately stop and adjust if there is a problem.

2. Hydraulic drive

It is completed by a high-precision cylinder and piston, and linear motion is achieved through the relative movement of the cylinder and the piston rod.

Advantages: high power, can save the reduction device directly connected with the driven rod, compact structure, good rigidity, fast response, servo drive has high precision.

Disadvantages: It is necessary to add a hydraulic source, which is prone to liquid leakage and is not suitable for high and low temperature occasions. Therefore, hydraulic drives are currently mostly used in super-powered robot systems.

Choose suitable hydraulic oil. Prevent solid impurities from mixing into the hydraulic system, and prevent air and water from intruding into the hydraulic system. The mechanical operation should be gentle and smooth. The mechanical operation should avoid roughness, otherwise the impact load will inevitably occur, which will cause frequent mechanical failures and greatly shorten the service life. Pay attention to cavitation and overflow noise. Always pay attention to the sound of the hydraulic pump and the overflow valve during operation. If the hydraulic pump has "cavitation" noise, which cannot be eliminated after exhausting, it should be used after finding out the cause and troubleshooting. Maintain proper oil temperature. The working temperature of the hydraulic system is generally controlled between 30 and 80°C.

3. Pneumatic drive

The pneumatic drive is simple in structure, clean, sensitive in action, and has a buffering effect. But compared with the hydraulic drive device, it has lower power, poor rigidity, high noise and difficult speed control, so it is mostly used for point control robots with low precision.

(1) It has the characteristics of fast speed, simple system structure, convenient maintenance and low price. Suitable for use in robots with medium and small loads. But because it is difficult to realize servo control, it is mostly used in program-controlled robots, such as loading and unloading and stamping robots.

(2) In most cases, it is used in small and medium robots that realize two-position or limited-point control.

(3) At present, most control devices use programmable controllers (PLC controllers). In flammable and explosive situations, pneumatic logic components can be used to form a control device.

2. Linear transmission mechanism

The transmission device is the key part connecting the power source and the motion link. According to the joint form, the commonly used transmission mechanism includes linear transmission and rotation transmission mechanism.

Linear drive can be used for X, Y, Z drive of Cartesian coordinate robot, radial drive and vertical lift drive of cylindrical coordinate structure, and radial telescopic drive of spherical coordinate structure.

The linear motion can be converted into linear motion by transmission elements such as rack and pinion, screw nut and other transmission elements. It can also be driven by a linear drive motor, or it can be directly generated by a cylinder or a piston of a hydraulic cylinder.

1. Gear rack device

Usually the rack is fixed. The rotational movement of the gear is converted into the linear movement of the pallet.

Advantages: simple structure.

Disadvantages: large return difference.

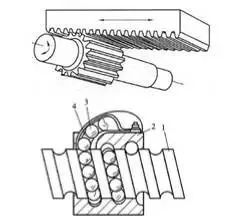

2. Ball screw

The ball is embedded in the spiral groove of the screw and the nut, and the ball can circulate continuously through the guide groove in the nut.

Advantages: low friction, high transmission efficiency, no crawling, high precision

Disadvantages: high manufacturing cost and complex structure.

Self-locking problem: In theory, the ball screw pair can also be self-locking, but the self-locking is not used in practical applications. The main reasons are: poor reliability or high processing costs; because the ratio of diameter to lead is very large, Generally, a self-locking device such as a worm gear is added.

3. Rotating transmission mechanism

The purpose of adopting the rotation transmission mechanism is to convert the higher rotation speed output by the driving source of the motor into a lower rotation speed and obtain a larger torque. The most commonly used rotation transmission mechanisms in robots are gear chains, synchronous belts and harmonic gears.

1. Gear chain

(1) Rotation speed relationship

(2) Torque relationship

2. Timing belt

The timing belt is a belt with many profiled teeth, which meshes with a synchronous pulley that also has profiled teeth. It works like a soft gear.

Advantages: no sliding, good flexibility, low price, high repeat positioning accuracy.

Disadvantages: a certain amount of elastic deformation.

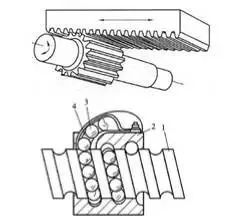

3. Harmonic gear

Harmonic gear is composed of three main parts: rigid gear, harmonic generator and flexible gear. Generally, the rigid gear is fixed, and the harmonic generator drives the flexible gear to rotate.

main feature:

(1) The transmission ratio is large, and the single-stage is 50-300.

(2) Smooth transmission and high carrying capacity.

(3) The transmission efficiency is high, up to 70%-90%.

(4) High transmission accuracy, 3-4 times higher than ordinary gear transmission.

(5) The return difference is small, which can be less than 3'.

(6) The intermediate output cannot be obtained, and the rigidity of the flexspline is low.

Harmonic transmission devices have been widely used in countries with more advanced robotics technology. As far as Japan is concerned, 60% of robot drive devices have adopted harmonic drive.

The robot sent to the moon by the United States uses harmonic transmission in each joint part, and one of the upper arms uses 30 harmonic transmission mechanisms.

The "Moon Lander", a mobile robot sent to the moon by the former Soviet Union, has eight wheels installed in pairs that are individually driven by a closed harmonic drive mechanism. The ROHREN and GEROT R30 robots developed by the German Volkswagen Company and the VERTICAL 80 robots developed by the French Renault Company all adopt a harmonic drive mechanism.

4, the robot sensing system

1. The sensing system is composed of internal sensor modules and external sensor modules to obtain meaningful information from internal and external environmental conditions.

2. The use of smart sensors improves the mobility, adaptability and intelligence of the robot.

3. The use of smart sensors improves the mobility, adaptability and intelligence of the robot.

4. For some special information, sensors are more effective than human perception systems.