Humans want to achieve a series of basic activities, such as life, work, and study, they must rely on their own organs. In addition to the brain, the most important thing is our eyes. (Industrial) robots are no exception. They must complete normal production tasks. Without a complete set of advanced vision systems, it is difficult to imagine.

The machine vision system uses machines instead of human eyes to make various measurements and judgments. It is an important branch of computing. It integrates technologies such as optics, mechanics, electronics, computer software and hardware, and involves computers, image processing, pattern recognition, artificial intelligence, signal processing, optomechanical integration and other fields . The rapid development of image processing and pattern recognition technologies has also greatly promoted the development of machine vision.

Understand the robot vision system

Generally speaking, a machine vision system includes a lighting system, a lens, a camera system, and an image processing system. For each application, we need to consider the operating speed of the system and the image processing speed, whether to use a color or black and white camera, the size of the detection target or whether the detection target has defects, how large the field of view needs to be, how high the resolution needs to be, and how large the contrast needs to be Wait.

From a functional point of view, a typical machine vision system can be divided into: image acquisition part, image processing part and motion control part.

機人視覺系統(tǒng)優(yōu)點

1. Non-contact measurement will not cause any damage to the observer and the observed, thereby improving the reliability of the system.

2. It has a wide spectral response range, such as using infrared measurement that is invisible to the human eye, which expands the visual range of the human eye.

3. Working stably for a long time, it is difficult for humans to observe the same object for a long time, while machine vision can do measurement, analysis and recognition tasks for a long time.

4. The application fields of machine vision systems are becoming more and more extensive. It has been widely used in industry, agriculture, national defense, transportation, medical treatment, finance, and even sports, entertainment and other industries. It can be said that it has penetrated into all aspects of our life, production and work.

In simple terms, the vision system can be summarized by three independent and interconnected modules: target image acquisition, image processing, and command issuance.

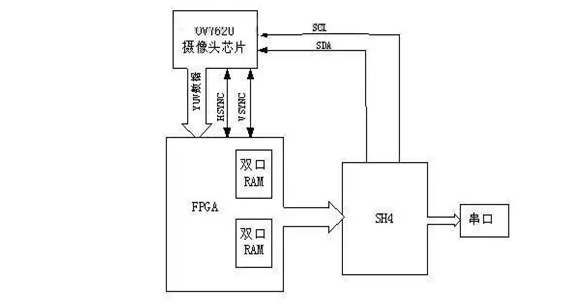

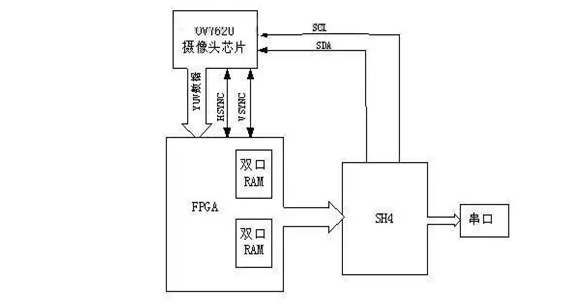

(1) The hardware design of the vision system

The hardware of the vision system is mainly composed of a lens, a camera, an image capture card, an input and output unit, and a control device.

The quality of a vision system depends on the level of the camera's pixels, the quality of the hardware, and more importantly, the coordination and rational use of the various components.

(2) The software design of the vision system

The software design of the vision system is a complicated subject. It is necessary to consider not only the optimization of program design, but also the effectiveness of the algorithm and whether it can be realized. In the process of software design, it is necessary to consider possible problems.

The software design of the vision system must be tested and improved to adapt to the complex external environment.

Robot vision hardware mainly includes two parts: image acquisition and vision processing, and image acquisition is composed of lighting system, vision sensor, analog-digital converter and frame memory. Robot vision acquires a two-dimensional image of the environment through a vision sensor, analyzes and interprets it through a vision processor, and then converts it into a symbol, allowing the robot to recognize the object and determine its location.

The specific process is as follows:

The difficulty of industrial machine vision lies in accuracy and speed, and the requirements are in the millimeter level, and the movement of the industrial robot's gripper in the industrial field is in a three-dimensional space. According to different functions, robot vision can be divided into two types: visual inspection and visual guidance.

1. Food safety monitoring

In streamlining production and product quality inspection, machine vision is required to observe, identify, and find errors and omissions in the production process.

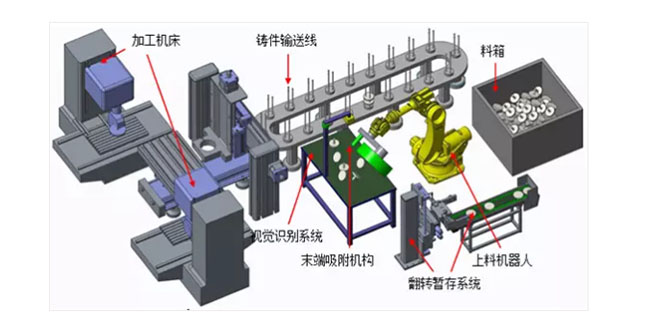

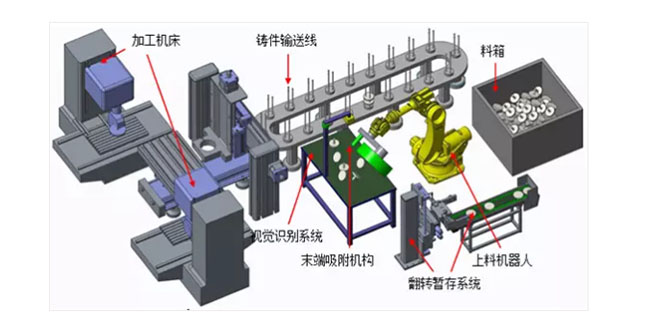

2. Manufacturing

The characteristic of the machine vision system is to improve the flexibility and automation of production. In some dangerous working environments that are not suitable for manual operations or occasions where artificial vision is difficult to meet the requirements, machine vision is often used to replace artificial vision;

At the same time, in the mass industrial production process, manual vision is low in efficiency and accuracy. Machine vision inspection can improve production efficiency and production automation, and it is easy to achieve information integration.

3. Solar energy, traffic monitoring

Solar cell and module producers use machine vision to inspect products, identify and track products, and assemble products.

In the field of traffic monitoring, it can be applied to license plate recognition technology, image analysis technology, automatic license plate recognition, detection of illegal parking, retrograde, and detection of traffic accident vehicles.

Traditional manufacturing is facing new subversion, and transformation and upgrading will bring huge market opportunities to China's automation industry. As a highly intelligent product in the automation industry, machine vision has huge development potential in the future.

In the past few years, Chinese electronics manufacturers and foundries have been purchasing a large number of automation equipment to replace labor in order to cope with China’s growing shortage of labor. This phenomenon will reach a climax in the next few years. Taiwan-funded factories have chosen to increase the degree of automation, and the climax of automation will come in the next 2-3 years, which will surely bring new growth points to the application of machine vision products in this industry.