Productivity is an important factor to measure the production volume of a company. Especially for manufacturing companies, effectively improving production efficiency is the key to reducing production costs. In the process of product production, if you want to improve production efficiency, you generally need to use automated assembly line equipment. In the process of mass production, if the automated production assembly line equipment is unreasonably assembled, it will make workers uneven and cause waste. The phenomenon of manpower, then how should we improve the production efficiency of automated assembly line equipment?

First, the design of the assembly line

The market group of assembly line equipment is the enterprise, and the situation of each enterprise is unique. The design of assembly line equipment needs to be established on the basis of the actual situation of the enterprise, and the rationality of the design directly affects the quality of the product, thereby affecting the operational efficiency and production efficiency of the enterprise's production. Therefore, when choosing to invest in automated pipeline equipment, the first consideration should be whether the manufacturer of the manufacturing pipeline has the ability to design non-standardization, and whether the program design is reasonable and waiting for factors. Hongtu has been designing and manufacturing assembly lines for more than 13 years. Equipped with a senior engineering team, Hongtu provides enterprises with assembly equipment solutions that meet their own production requirements, and manufactures equipment that can increase profits for enterprises!

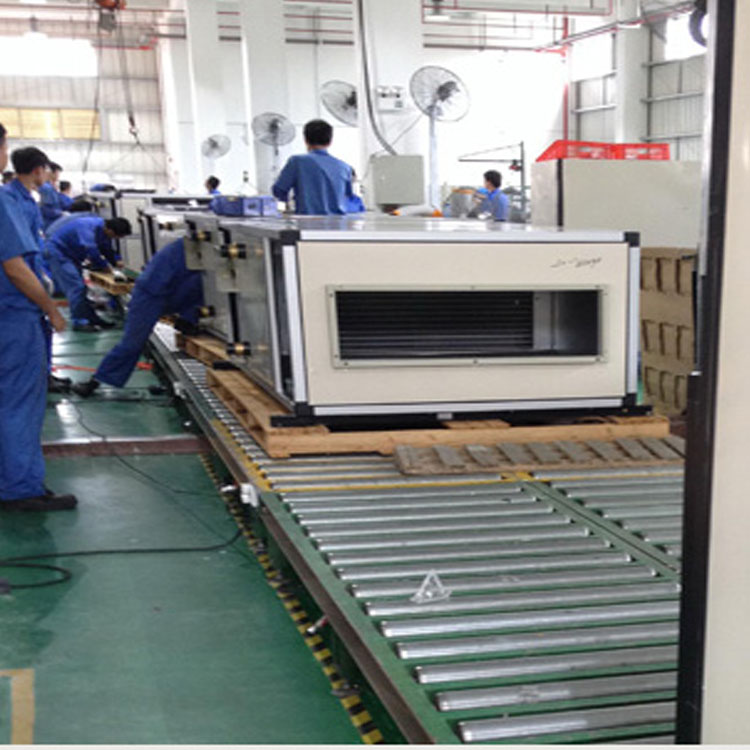

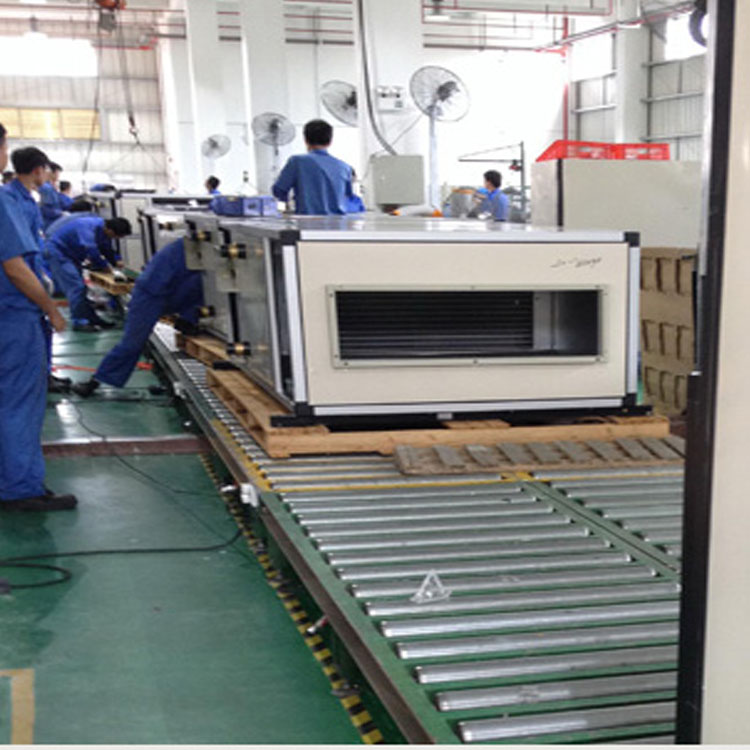

Second, production layout

The layout of production and operation of assembly line equipment in the workshop is also very important, and the layout should be reasonable according to the limited space of the workshop, so as to be as simple and clear as possible. At the same time, it is necessary to take into account the operating habits of the production operators. If the assembly line equipment layout is too messy or complicated, it will reduce the production efficiency of online operators.

Third, production management

To improve the operating efficiency of assembly line equipment, it is inseparable from formal and effective management. Effective production management can standardize production and operation, thereby forming an effective and rapid response mechanism, and can handle emergencies in production in a timely manner.

Fourth, regular maintenance

Regular maintenance can effectively prevent hidden dangers caused by excessive aging and wear of assembly line equipment. Enterprises need to regularly overhaul the assembly line equipment, and replace worn-out parts in time. Only in this way will the equipment fail to cause a waste of manpower and material resources during use. If the problem in the key part cannot be solved, you can contact the manufacturer for maintenance.

The above four points are some methods and measures on how to improve the production efficiency of assembly line equipment. Only after we have mastered these methods and measures, can the work process be more smooth.

This article is from Hongtu Automation http://techint.com.cn, if you need to forward, please note the source, thank you!